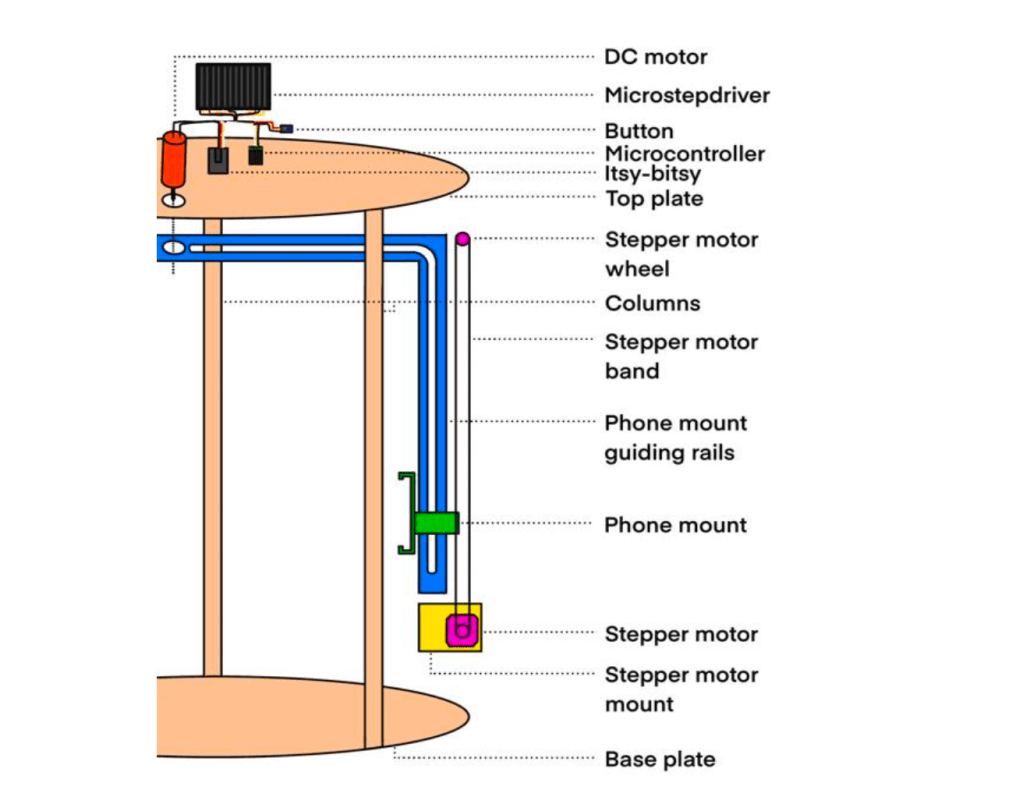

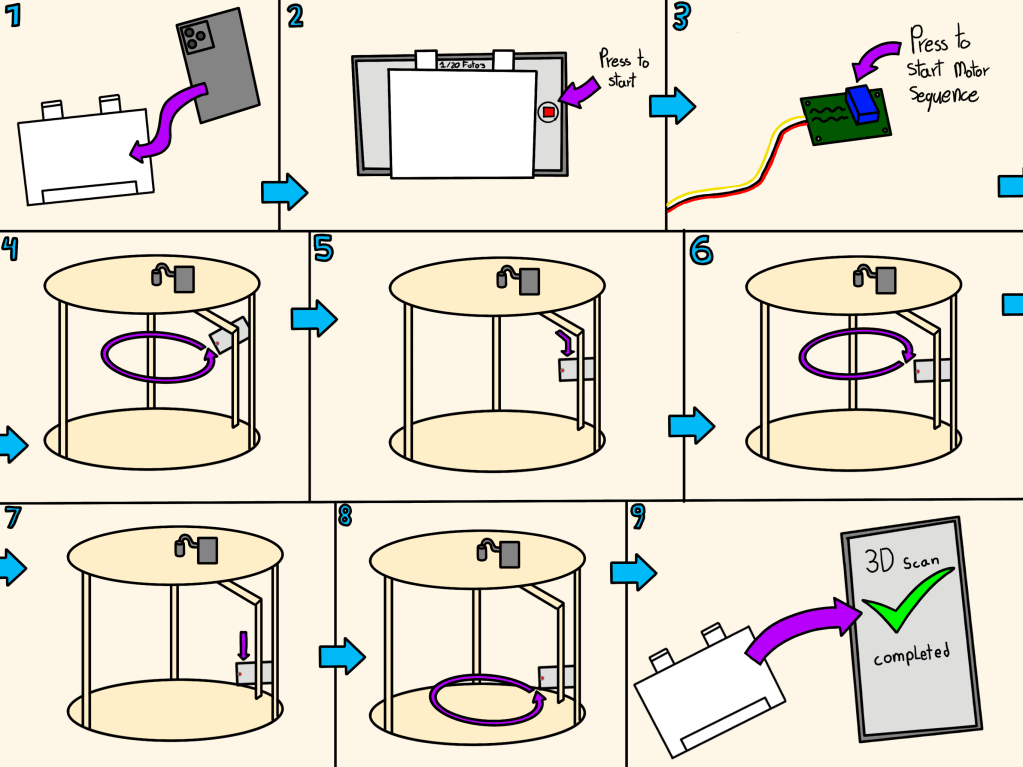

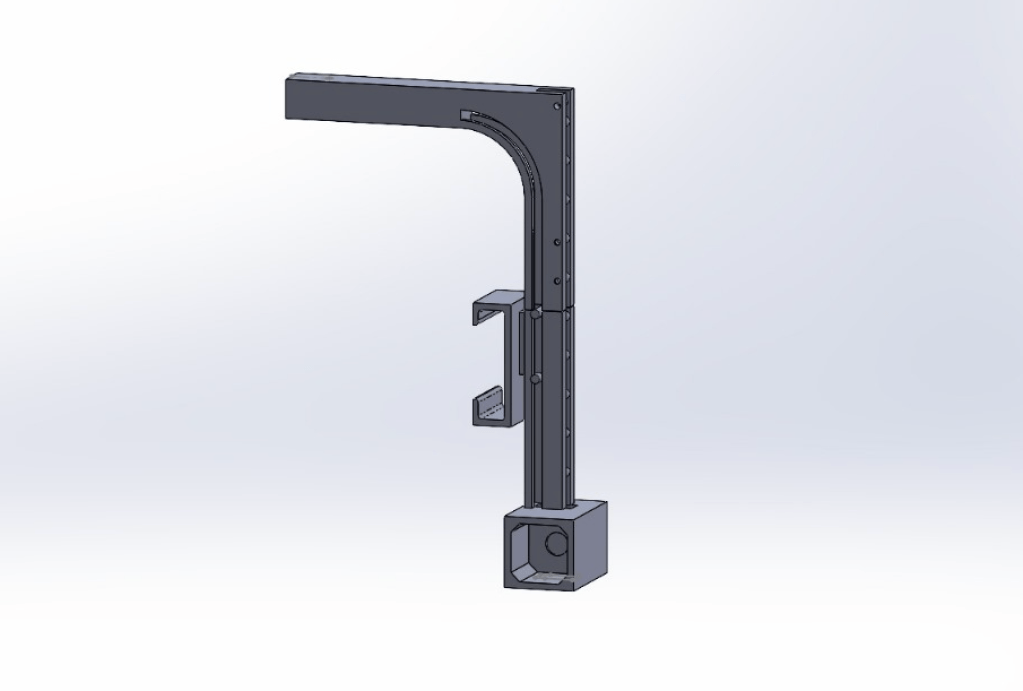

This project we developed a fully automated 3D scanner using a custom-built rig powered by stepper and dc motors, 3D printed parts, Arduino code and a phone to precisely rotate and elevate the phone around an object for a detailed scan.

My Role

Concept Designer

Frame and Arm Construction

Motor Setup

Electronics and wiring

System testing with Polycam

Time

3 Months

Overview

This project explores how a smartphone can become a fully automated 3D scanner using custom-built hardware and the Polycam app. With CNC-cut wood, 3D printed parts, and Arduino-controlled motors, the rig smoothly spins and lowers the phone around an object. Through iterative prototyping, we tackled challenges, refining the design into a precise, press-to-scan experience.

3 Primary Problems

1. Accessibility

Making an affordable 3D scanner that is easy to use by utilizing your smartphone .

2. Precision

Controlled motion for accurate scans using custom mechanics and motor control.

3. Automation

Eliminating manual movement by automating the scanning process.

Opportunity

This project shows how everyday technology like a smartphone can be enhanced with custom hardware to create low-cost, accessible tools for digital fabrication opening doors for makers, educators, and designers.

Iteration

Final Concept

Custom-built rig that, when combined with a smartphone and the Polycam app, automates the 3D scanning process by precisely rotating and elevating the phone around an object.

Reflection

The making of this project came with a bunch of challenges, from microcontroller programming to mechanical integration, system assembly to achieve consistent results, especially belt tensioning to use with a stepper motor and the weight of various phones caused a lot of trial and error. But we ended up with a working prototype and it taught me a lot. Especially about prototyping and electromechanical systems.