A prefabricated, material-driven roof solution that solves durability, performance, and scalability issues in container housing.

My Role

Material-driven concept development

Technical design & CAD

Structural reasoning & simulation-based validation

Stakeholder analysis & value prioritization

Market, feasibility, and cost modeling

Sustainability assessment & lifecycle reasoning

Time

3 Months

Overview:

Container homes are increasingly used as an affordable and sustainable housing alternative, but they suffer from a fundamental weakness: flat steel roofs that trap water, corrode quickly, and shorten the building’s lifespan.

This project investigates how Sheet Molding Compound (SMC) can be used to address that weakness through a prefabricated roof system. By focusing on the roof as the most failure-prone component, the design improves durability, thermal performance, and installation efficiency while remaining compatible with standardized 20ft and 40ft containers.

The final outcome is a two-part SMC structural system combined with standardized sandwich panels, designed for scalability, fast installation, and real-world manufacturability.

3 Primary Problems

1. Durability

Flat container roofs cause water pooling, leading to corrosion and premature structural failure. This drastically reduces the usable lifespan of container homes.

2. Implementat-ion

Despite containers being standardized products, current roof solutions rely on custom-built constructions that are slow, expensive, and difficult to scale.

3. Sustainability

When container homes fail early, their embodied material and environmental value is wasted, undermining their promise as a sustainable housing solution.

Opportunity

By leveraging SMC’s weather resistance, form freedom, and production accuracy, there is an opportunity to create a universal, prefabricated roof system that extends container lifespan, reduces maintenance, and enables scalable upcycling of shipping containers into long-term housing.

This is where your project moves from “interesting” to commercially and socially relevant.

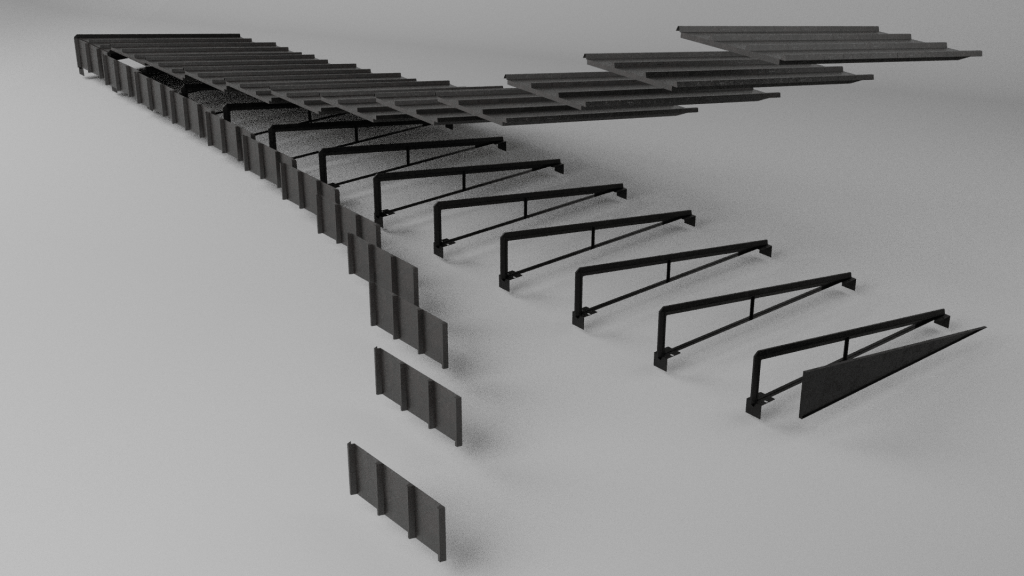

Iterations

Concept Video

Final Concept

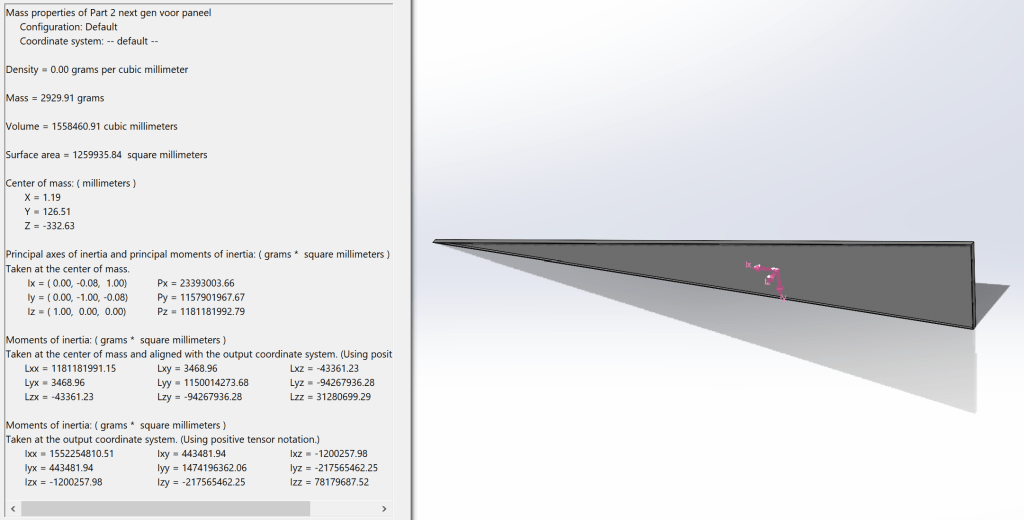

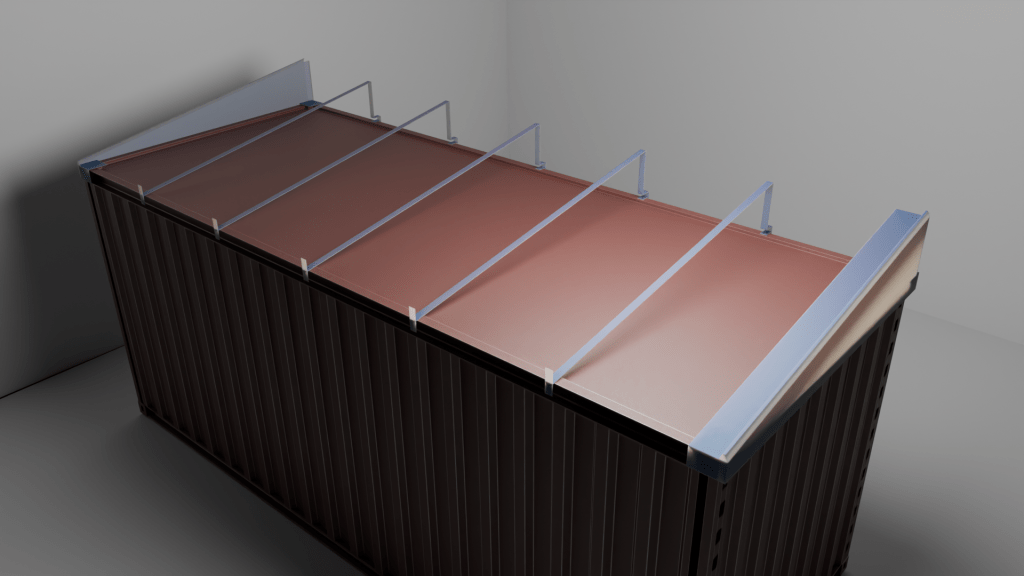

The final concept is a prefabricated SMC roof system compatible with both 20ft and 40ft container homes. It consists of only two SMC components: a repeating structural mounting part and an end cap. These components anchor standardized steel sandwich panels while creating a sloped, sealed, and insulated roof assembly.

The system bolts directly onto existing container corner castings and edges, allowing fast installation, minimal customization, and efficient large-scale production.

Reflection

This project forced a shift from solution-first thinking to problem-led, market-aware design. Early concepts were technically interesting but commercially unrealistic. Through iteration, stakeholder feedback, and feasibility analysis, the design was reduced from five unique parts to two dramatically improving manufacturability and scalability.

The biggest learning was that good design is often about reduction, not addition. By aligning material properties, production logic, and market constraints, the final concept became both technically robust and realistically viable. While real-world testing is still required, the project establishes a solid foundation for further development and industrial implementation.